› RC BOATING › YACHTING › Builds › 3D Printed Yacht Stand

Tagged: RC Yachts

- This topic has 2 replies, 2 voices, and was last updated February 4, 2019 at 5:01 pm by

Kermit.

Kermit.

-

AuthorPosts

-

-

30 January 2019 at 20:43 #2483

Here is a little project I have been working on for a while.

A 3D printed yacht stand that will fit both the DF65 & 95 (and anything else that’s a similar size)

Cheap to build, $5 for a length of conduit, around $10 worth of filament and a few S/S screws.

All parts will fit on a small printer except for the keel board, but you can use a piece of plywood or plastic sheet for this.

All the files are on thingiverse to download.

https://www.thingiverse.com/thing:3391502DF95

DF65

Printed parts

Printed Parts,

All printed in PETG except for the feet and collars, which are printed in a flexible filament.

Cradle, 2 off

5mm Hinge Washers, 2 off

Frame Hinge, 2 off

Tube Washers, 6 off

20mm Plug, 2 off

20mm Plug Slotted, 2 off

Catch, 1 off

Drill Jig, 1 off

Feet, 4 off

Collar, 2 off

Tee – right, 2 off

Tee – left, 2 off

Keel Support, 1 offHardware,

20mm Electrical conduit.

M5 X 50mm, S/S Pan Head Screws, 6 off

M5 S/S Nylock Nuts, 6 off

4G X 10mm S/S Self tapper screws.Instructions,

1. Cut conduit into the correct lengths.

2 X 500mm, Long legs

2 X 310mm, Short legs

2 X 232mm, Cross braces for small frame

1 X 285mm, Cross brace for large frame

1 X 290mm, Handle

2. Drill the 5mm holes in the long legs using the drill jig as these dimensions are critical.

3. Bolt the long legs to the cradles using the M5 X 50mm screws.

4. Assemble the small frame

5. Use two M5 X 50 screws to join the two frames together with the printed 5mm hinge washers between.

6. Slide the 20mm handle into the cradles with the catch with a collar on either side. (the collars are just to keep the brace in the centre of the stand).

7. Screw the keel support to the long legs. 380mm from the top of the legs to the top of the support, using 4G Self Tappers, then fit bottom cross brace for the long legs.

8. Put some padding on the cradle arms to protect the yacht.

9. Push in the feet and conduit plugs.

10. Go sailing! -

4 February 2019 at 15:39 #2487

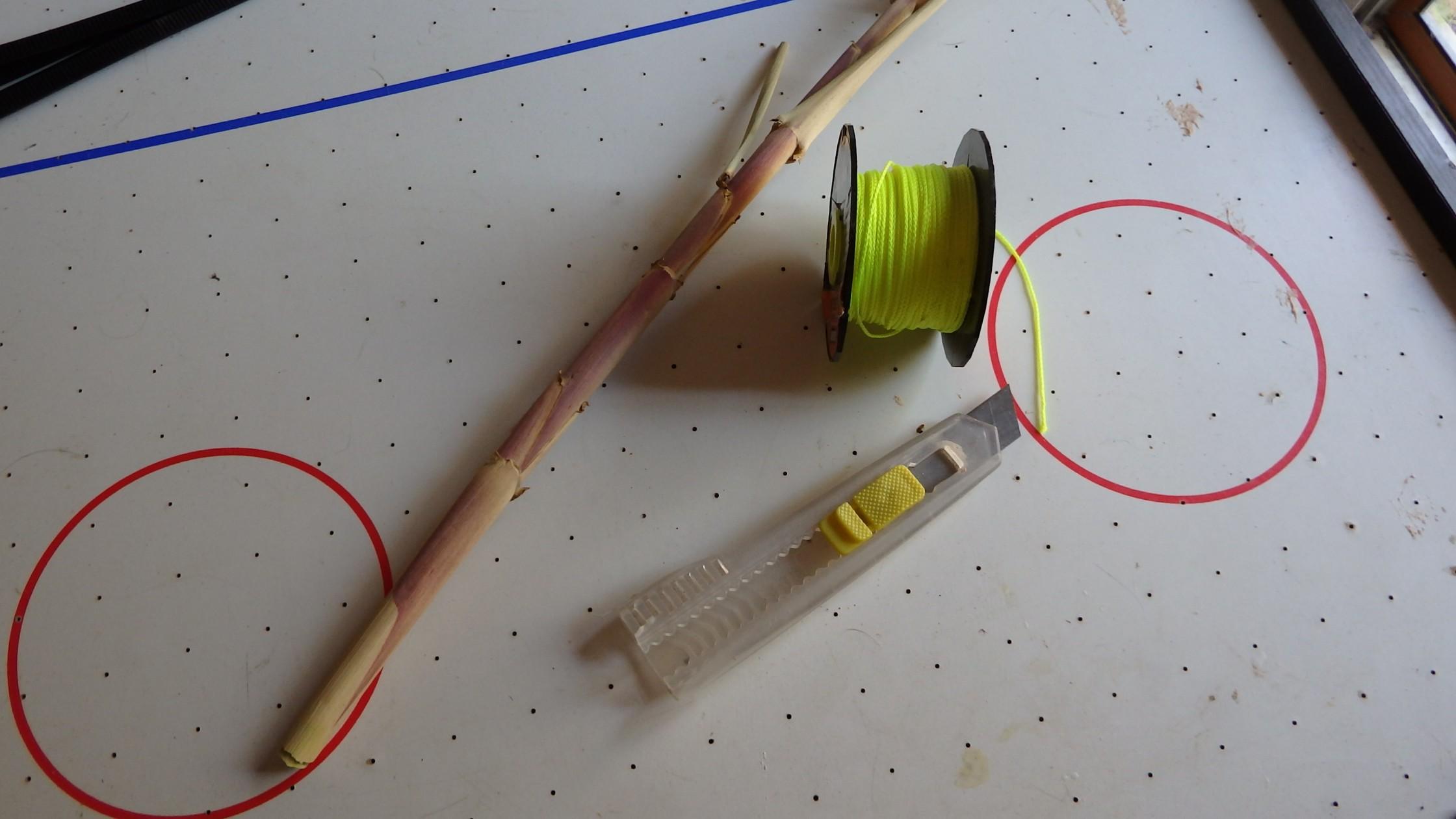

BRILLIANT……. I ALSO HAVE built a stand using local material its fast to build portable and does not use nuts and bolts if I get enough requests for it I will go into production……this is an environmental sustainable product No 3D printer for this product just good ol bamboo locally made Comes with green string at no extra cost

-

4 February 2019 at 17:01 #2489

-

-

AuthorPosts

- You must be logged in to reply to this topic.