Forum Replies Created

-

AuthorPosts

-

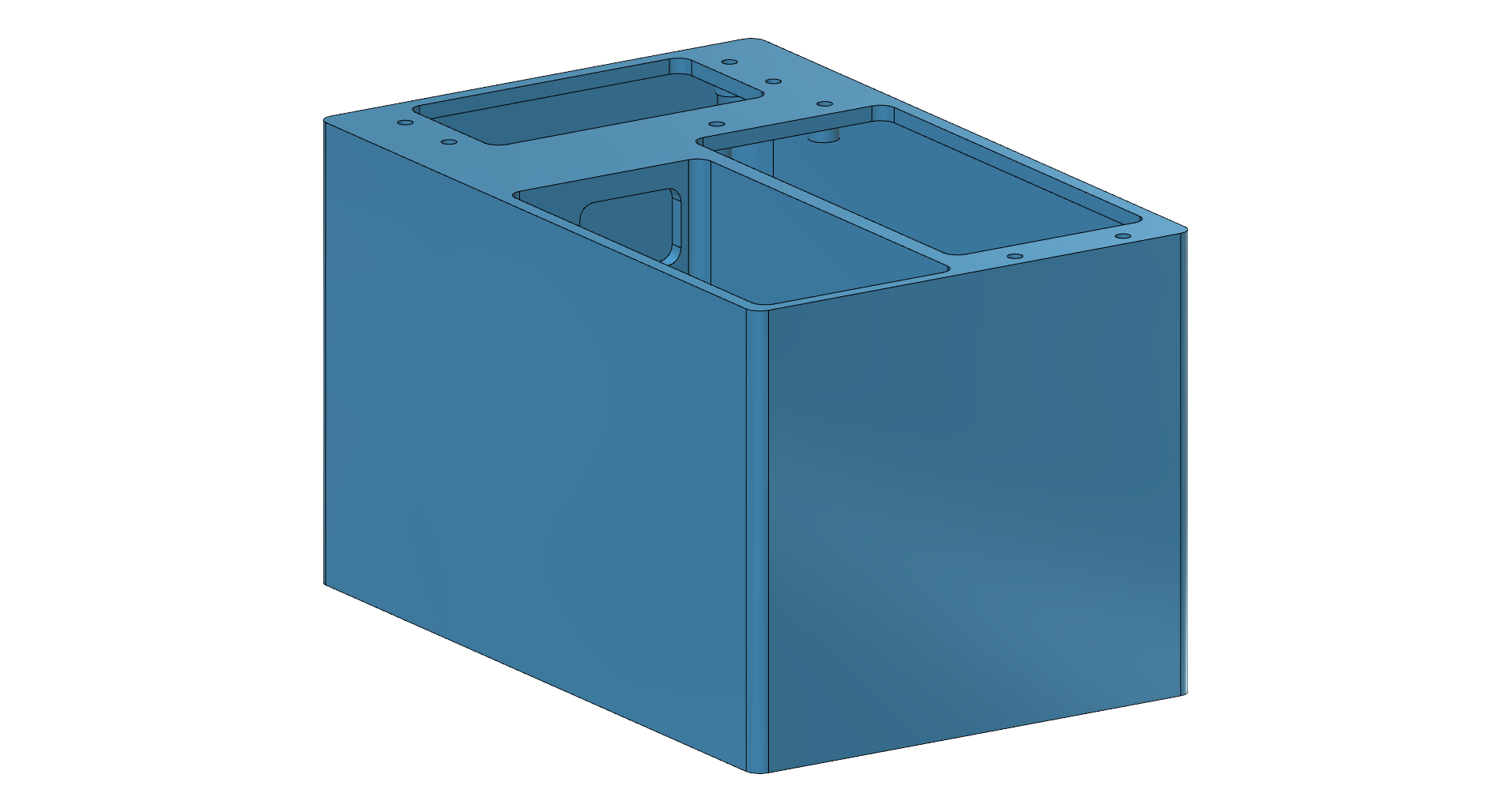

Got the servo box designed & printed (10 hr print) yesterday so hopefully get the servos fitted & all reinstalled today.

If I got the measurements correct there should be room for both the sail winch & Rudder servo, as well as a 5 cell AA NiMh battery pack.

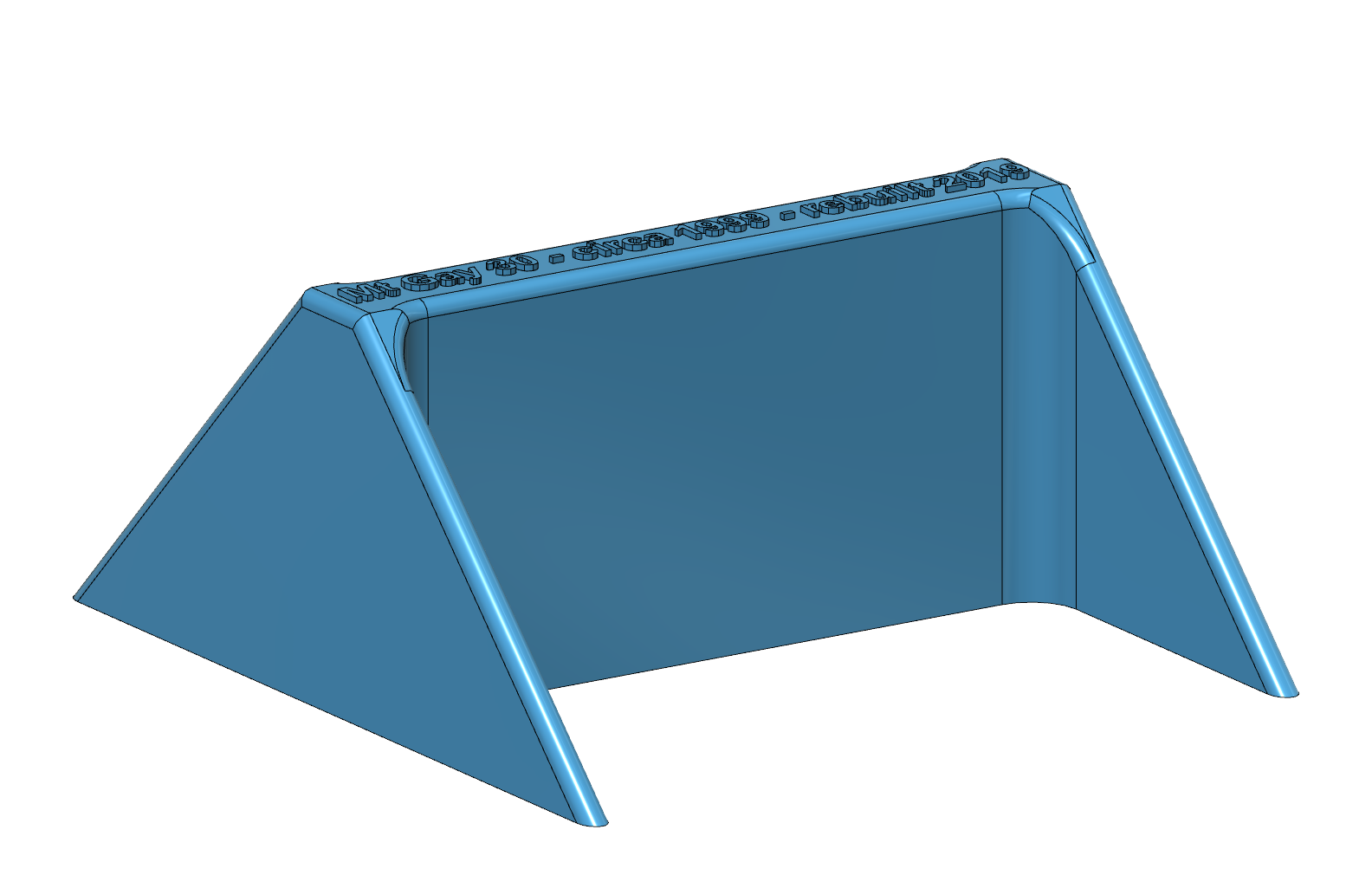

Keelbox & support bracing is next on the list for 3D printing.

Design is complete & printing now underway.

Keelbox & bracing to go over & secure the alloy keel fin to the hull

Once this is epoxied in place the Servo tray can be completed & installed then I can think about refitting the deck and making sure it is sealed this time, which is where the job started

Update:

Keel box now installed.

The keel fin has now been fibre-glassed into the hull & reinforced with woven glass mat and the forward bulkhead (in fact the ONLY bulkhead) that sits under the mast has been reinstalled & epoxied into place.

Keel fin & forward bulkhead

Next job is to finish off the design of the new 3D printed Servo Tray and get that fitted so I can see where the keel fin bracing needs to be installed.

Yes Kermit, the 3D printer certainly makes modelling a whole lot easier & quicker.

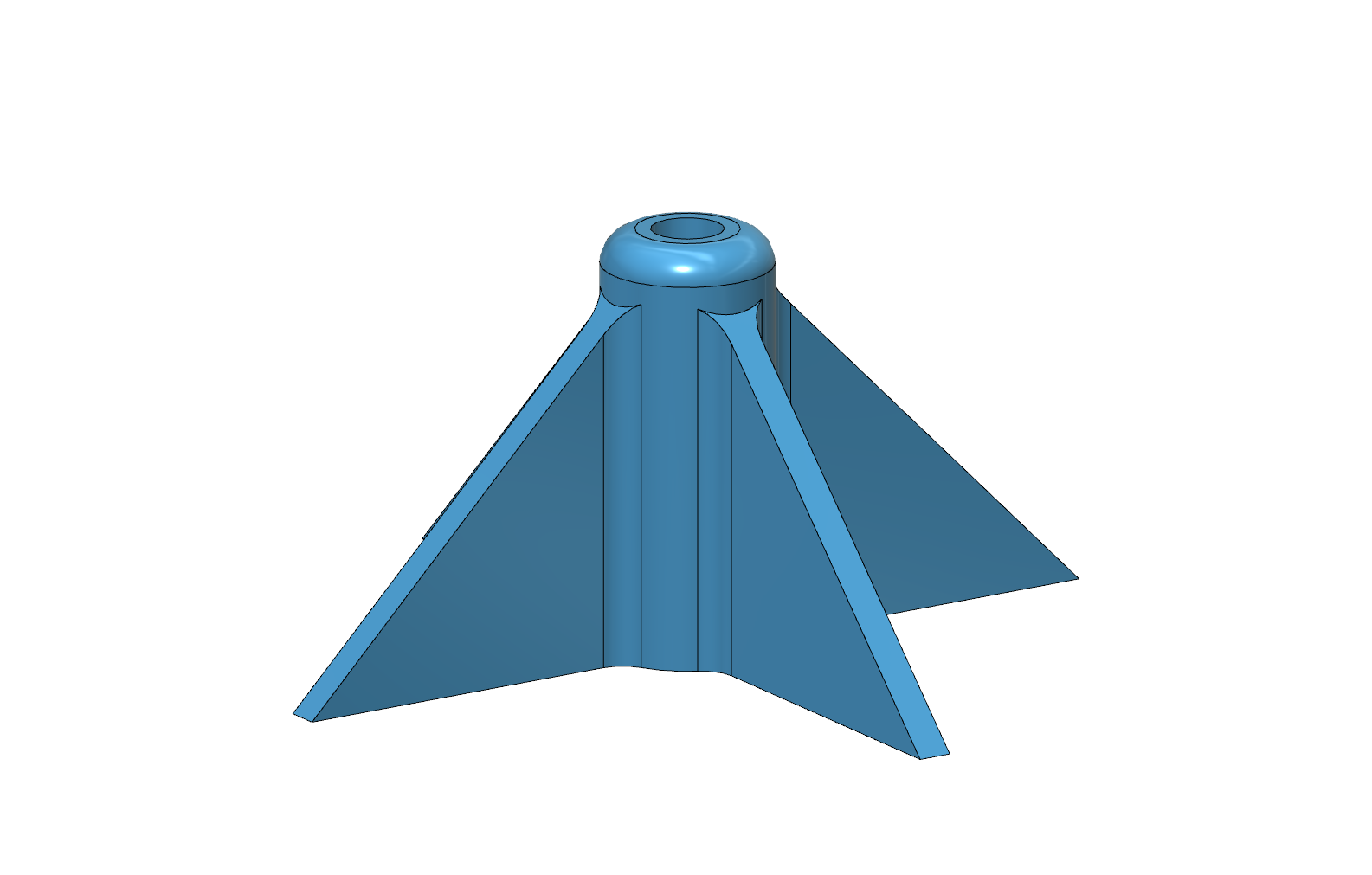

Seeing as I’m stuck inside on this cold, wet & windy day its a good time to get things done so moving right along with the repairs the new rudder support post has been designed, printed & fitted to the Badger II.

The 3D design ready for printing

New Rudder Support Post- Printed & epoxied into place

New Rudder Support Post- Printed & epoxied into placeThe original Rudder mounting block that had come unstuck from the hull

After a recent sailing @ Puddleduck chasing another Mt Gay & a few DF65’s the poor old Badger II was found to be carrying a significant amount of water ballast. With so much water inside her it was easy to spot the leak.

It turned out that virtually the whole hull to deck join was badly leaking so all the previous work waterproofing the hatches was having little or no effect.

At first it was thought that some self levelling epoxy poured into the inverted hull may have been enough to fix the problem but on closer camera inspection of the joint from inside the hull it was decided to remove the entire deck and start again.

The timber Servo/radio/battery/keel mountings had already been removed as they were showing signs of water-logging over a long time & their removal allowed for easier internal access to the hull.

Control Gear Timberwork & bulkhead removed

Inverted deck (after removal)

The hull (with deck removed)

I guess glues weren’t as good 20 years ago or else “Badger II” was built more as a display model but whichever the reason there was very little persuasion required to get everything unstuck with the only damage being the rubbing board around the deck which came off in quite a few pieces.

First order of the day will be fibreglass the alloy keel into the hull then 3D print & install mounting braces for the keel & rudder post. Once that is done then a new timber deck mounting rail will be installed & sealed followed by refitting the deck after a bit of a clean up.

Not sure yet but I may just fit a new deck entirely as it may be easier.

To Be Continued…

I’m not sure what Ricky’s weighs, it was more just a check to see if the weight goes up or down with the new 3D printed parts in place of the wood.

Another fine day @ the Duck, enjoyed by everyone, even with the weed in the early races.

As for the water leak alluded to by Col in my Mt Gay 30 (it was definitely significant but in no danger of sinking).

Anyway, the “Badger II” has been stripped down and all the old timber servo & keel mounts removed to give good access to reseal the inside of the deck to hull join.

I guess after 20 odd years things have got to fail eventually.

During the rebuild all the removed timber bits & pieces will be replaced with lightweight 3D printed bits.

The alloy keel fin will be fibre-glassed into the hull. This will be a lot sturdier than the original timber sandwich mount which was showing signs of being waterlogged one too many times. The servo mounts were also in similar condition.

For those that were enquiring today, before the strip-down the Mt Gay sailing weight was 3.33kg all up.

How it looked to start with

How it looks now (still need to remove the baseboard)

The Scraps

Yes, it was a fine day for canal sailing (even with the chilly wind a blowing) & the lunchtime BBQ was a classic.

Sounds like the hardy crew that turned up despite the winter weather thoroughly enjoyed themselves.

Well after the “Splashdown” landing yesterday most of the electronics in the SkyClimber had stopped working due to water ingress.

Removed, dismantled & dried out the receiver and now that tests OK again on all 8 channels. It was amazing how much water was still trapped inside it, even after hanging up all night in an air conditioned room.

After seeing the amount of water inside the receiver I figured that the Auto Pilot would probably be in the same condition. After removing & dismantling it water was found inside but no where near as much as the receiver had. It appears to have suffered no damage so after drying overnight while in pieces, I will re assemble & test in the morning.

The battery recharged OK after its dunking but not so the one from the Bix 2 that was parked in a tree all afternoon. Admittedly it was the same battery that spent 3 weeks up a tree a few months ago and it has flown every session since without problems but this time one cell has failed. I’ll have a look at converting it to 2S or else its destined for the scrap bin.

Have ordered a couple more Floureon 2200mAh 3s 25c LiPo’s as the previous ones I had have worked great since Nov 2016 so getting close to 3 years old now & still giving their full 15 minutes of flight time

Looks like another fun day was had by all. Sorry I couldn’t be there today.

Sounds like a great day (as usual) was had by all. Sorry I couldn’t be there but with IOM sailing tomorrow, flying Thursday, the canal on Saturday & IOM’s again on Sunday, I need to spend some time at home catching up with things. That said I should be there next Tuesday for the DF65’s & perhaps I better bring the Mt Gay along as well, sounds like a bit of match racing in the wind.

Kermit, if its for DF65 & 95 you need to talk to Kyle

I just realised that I never posted last weeks DF95 video.

-

AuthorPosts