Forum Replies Created

-

AuthorPosts

-

Kermit, thank you and your dragon, I just found the soup!

Your aim is getting better, it just missed hitting the roof this time.

I’m sure I will recover a lot faster now.

So now we know the truth of where the brick in my back yard came from.

Sorry cobber mate pal, I wasn’t there today. Feeling unwell so I stayed home away from everyone.

As for your video, you were right, nothing interesting, to many ducks, not enough boats, blurry picture in picture shots and soft focus.

A five-minute video stretched out to 25 minutes??? (Fell asleep 3 times) The only good part was my Ranger 1800 flying overhead.

As for Predators – GREAT videos, good close-ups, plenty of action shots, short and sweet, no soft focus, no ducks – If there was a GMA it would get my vote!

It beats using the pencil and ruler!

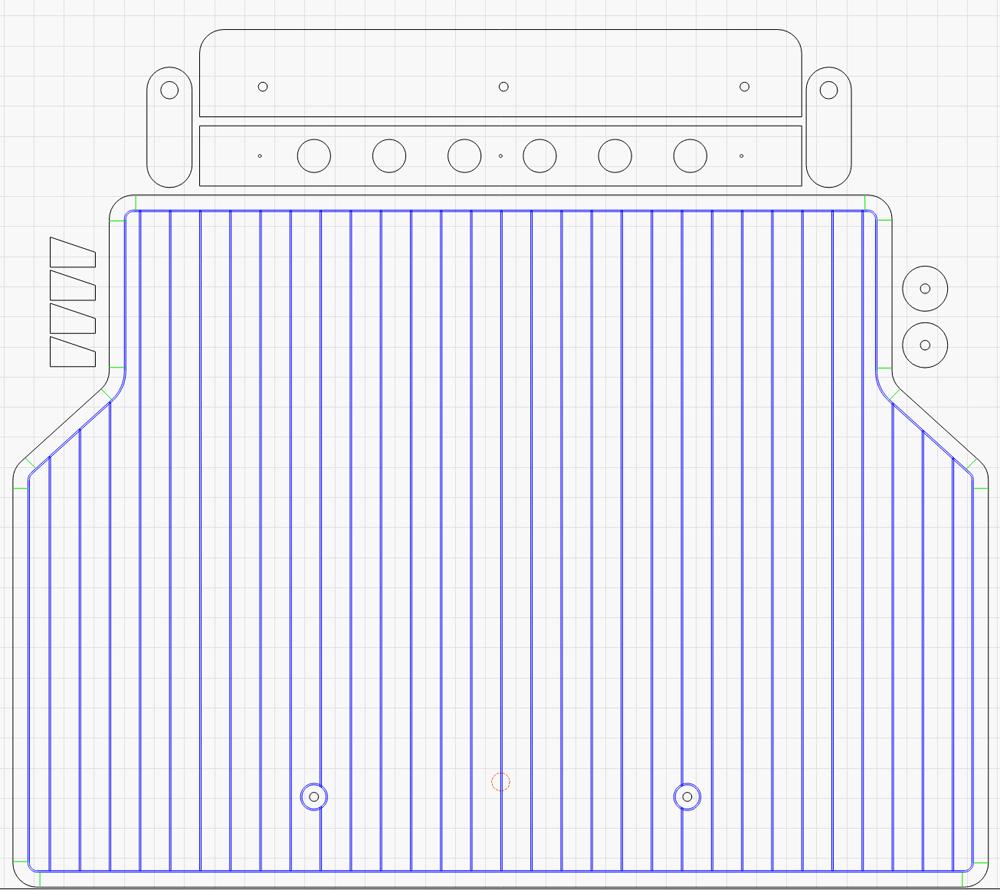

HOW TO LAY A PLANKED DECK – The easy way

The rear deck on the Cougar Cat was a piece of white plastic board.

So, onto the computer, draw a few lines on the screen.

Then a short time later, out of the laser engraver / cutter I had a nice wooden deck.

Sprayed a few coats of matt varnish on it and it’s done. (Even Kermit likes it)

You agreed with me???

Thats a bit better on the eyes.

How long did YouTube take to process it?

Interesting result Mike, but I only have two eyes and trying to watch four videos at once just doesn’t work?

What a great day at the canal, high tide, sunshine, light winds with the only downer being the floating weed.

This stayed close to the shore, so everyone got to play with their boats. A total of 12 boats on the water.

After the boating we headed up to the end of the canal for our monthly barbecue with the “Bloaters”, but they didn’t show, we had the barbecue cleaned and warmed up ready for them.

I suppose they might have been a bit intimidated by the large numbers of Marine Modellers in attendance, but we would welcome anyone (even Kermit)!

Also, I noticed on Kermit’s video he was trying to film our boats more than the yachts (we know yachts are a bit boring). You are welcome to come down to our end anytime and film Kermit, we won’t stir you too much.

My video,

Congratulations Kermit, well deserved.

A short one from today,

Kermit, do you know about this?

I feel safe, as you will have to find a plane that can actually fly and not crash!

Aren’t you Kermit’s protector, you will probably shoot me out of the water on Saturday, so why would I pay you?

I did wave back, but the camera was facing the other way then.

I did win the GMA and so did you! I could have won outright if I had voted for my own video, but I liked yours better.

-

AuthorPosts